At Allied Iron Products, quality is our top priority. We are dedicated to producing products that meet the highest international standards, with rigorous quality control processes in place. This includes validating suppliers, materials, and assessing our systems to ensure consistent excellence from production to delivery. Our comprehensive approach involves ongoing monitoring, testing, and supervision by qualified professionals.

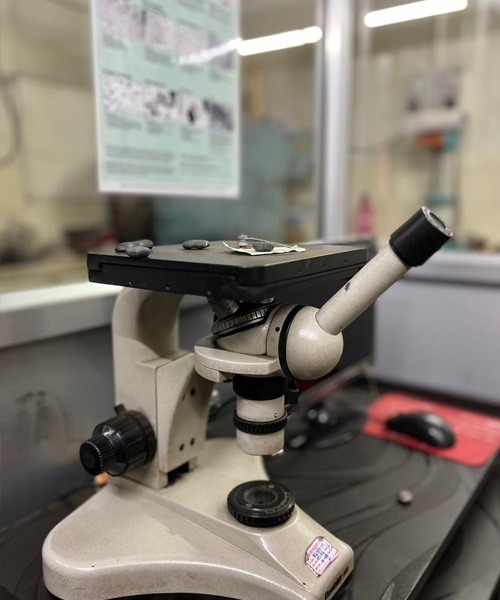

Our advanced in-house testing facilities include a load testing machine capable of testing up to 100 tons (1000kN) for product durability and a spectrometer that analyzes molten metal’s chemical composition for accuracy. We also perform dimensional inspections and use a microscope with an image analyzer to evaluate the material’s microstructure. Additionally, we maintain detailed manufacturing records through our PMS system, and we continuously improve processes based on customer feedback, ensuring accuracy, durability, and customer satisfaction

The entire foundry is certified to the quality system assurance standard ISO 9001:2015. Most of our products also hold international certifications, like the BSI Kitemark EN124:2015.

Quality and continuous improvement are part of our culture, it is embedded in our processes, our recruitment, and our training.